Hydroforming plastic is a manufacturing process involving high-pressure fluid to shape plastic materials into complex and intricate designs. This technique is commonly used in producing consumer goods, such as automobile parts, electronic components, and medical devices.

Hydroforming plastic is a highly versatile manufacturing process with a wide range of applications in various industries, including automotive, aerospace, and consumer products. Unlike other plastic forming techniques, hydroforming can produce complex and intricate designs in a single step, reducing material waste and tooling costs. However, as the demand for sustainable and eco-friendly manufacturing practices continues to grow, the environmental impact of hydroforming plastic has come under scrutiny.

Types of Hydroforming Plastic

Hydroforming Thermoplastics

Hydroforming thermoplastics involve using plastic materials that can be melted and reformed repeatedly without undergoing any significant chemical change. These plastics include polyethene, polypropylene, and polycarbonate. Hydroforming involves heating the plastic to its melting point, then forcing it into a mould using high-pressure fluid. Once the plastic has cooled and solidified, the mould is removed.

Hydroforming Thermosets

Hydroforming thermosets involve the use of plastic materials that undergo a chemical change when exposed to heat, forming a rigid, cross-linked structure that cannot be melted or reformed. These plastics include epoxy resins, phenolic resins, and melamine formaldehyde. Hydroforming involves heating the plastic to its curing temperature, forcing it into a mould using high-pressure fluid. Once the plastic has cured and solidified, the mould is removed, leaving behind a perfectly formed part.

Industrial Usage of Hydroforming Plastic

Hydroforming plastic is a versatile and cost-effective manufacturing process used in various industries, including automotive, aerospace, medical, and consumer goods. In the automotive industry, hydroforming plastic produces complex and lightweight parts, such as fuel tanks, engine covers, and instrument panels. In the aerospace industry, hydroforming plastic produces lightweight and aerodynamic parts, such as wing skins and fuselage panels. In the medical industry, hydroforming plastic produces intricate and precise parts, such as surgical instruments and implants. Hydroforming plastic produces a wide range of products in the consumer goods industry, including electronic housings, toys, and household appliances.

Application Areas of Hydroforming Plastic

Hydroforming plastic is used in a variety of application areas, including:

- Automotive industry: fuel tanks, engine covers, instrument panels, and structural components.

- Aerospace industry: wing skins, fuselage panels, and structural components.

- Medical industry: surgical instruments, implants, and diagnostic equipment.

- Consumer goods industry: electronic housings, toys, and household appliances.

- Packaging industry: containers, trays, and blister packs.

Consumer Product Examples

Hydroforming plastic is used in the production of many consumer products. Some examples include:

- Automotive parts: fuel tanks, engine covers, and instrument panels.

- Electronic components: housings, connectors, and brackets.

- Medical devices: surgical instruments, implants, and diagnostic equipment.

- Household appliances: vacuum cleaners, coffee makers, and blenders.

- Toys: action figures, building blocks, and puzzles.

Material Properties

Hydroforming plastic can produce parts with a wide range of material properties, including:

- High strength-to-weight ratio.

- High impact resistance.

- High chemical resistance.

- High temperature resistance.

- Low coefficient of friction.

- High dimensional stability.

Future Trends in Regards to Recycling:

In addition to the current recycling efforts, there are future trends in hydroformed plastic recycling. One such trend is the development of new recycling technologies that enable the recycling of thermoset plastics, which were previously considered non-recyclable. These new technologies involve the use of chemical processes that can break down the cross-linked structure of thermoset plastics, making them suitable for recycling.

Another trend in recycling hydroformed plastic is the adoption of closed-loop recycling systems, where the waste generated during manufacturing is collected, processed, and reused in the same production line. This approach can significantly reduce waste and material costs while also minimising the environmental impact of manufacturing.

Furthermore, as the demand for sustainable manufacturing practices continues to grow, there is also an increased focus on using recycled plastic materials in hydroforming processes. This approach can help reduce the amount of plastic waste in landfills and oceans while also conserving natural resources and reducing carbon emissions.

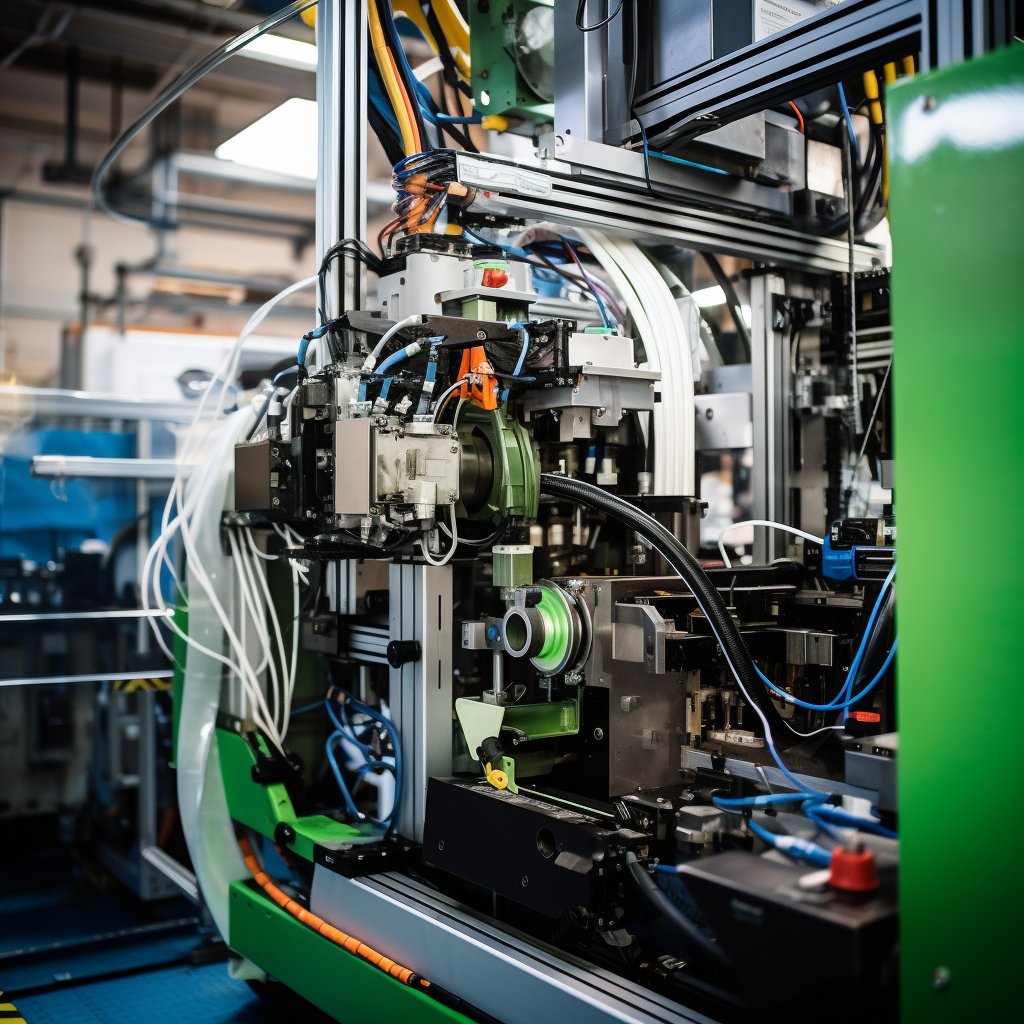

Hydroforming Process

Hydroforming involves high-pressure fluid to shape plastic materials into complex and intricate designs. The process begins with heating the plastic to its melting or curing point, depending on the type of plastic being used. The molten or cured plastic is then forced into a mould using high-pressure fluid, typically water or oil. Once the plastic has cooled and solidified, the mould is removed, leaving behind a perfectly formed part.

Advantages of Hydroforming Plastic

The hydroforming process offers several advantages over other plastic-forming techniques, including:

- Cost-effective: The hydroforming process can produce complex parts in a single step, reducing the need for multiple manufacturing steps and tooling.

- Versatile: Hydroforming can be used with a wide range of plastic materials, including thermoplastics and thermosets.

- High-quality parts: Hydroforming can produce high-quality parts with consistent wall thickness and excellent surface finish.

- Design flexibility: Hydroforming can produce complex and intricate designs that are difficult or impossible to produce using other forming techniques.

- Reduced material waste: The hydroforming process can reduce material waste by using only the amount of plastic necessary to produce the part, thereby minimising scrap and material costs.

Disadvantages of Hydroforming Plastic

Despite its advantages, the hydroforming process also has some disadvantages, including:

- Limited material selection: Some plastic materials cannot be used in hydroforming due to their low melting or curing points or inability to withstand the high-pressure fluid.

- High capital costs: The hydroforming process requires specialised equipment and tooling, which can be expensive to purchase and maintain.

- Environmental impact: The high-pressure fluids used in hydroforming can have environmental impacts if not managed properly.

Hydroforming plastics

Hydroforming plastic is a fascinating and valuable manufacturing process with various applications in various industries. Its ability to produce complex designs in a single step while minimising material waste and tooling costs makes it an attractive option for many manufacturers. However, as sustainability and environmental concerns become increasingly important, the industry must continue to find ways to reduce the impact of hydroforming plastic on the environment. Recycling and using eco-friendly materials are promising trends that can help achieve this goal.